Self-Drilling screws, also known as Tek Screws, can be identified by the shape of the screw – it is slightly curved at the end with a shape like a twist drill, whereas Self-Tapping screws can be tapped into various different types on material.

Self-Drilling Screws (TEK SCREWS)

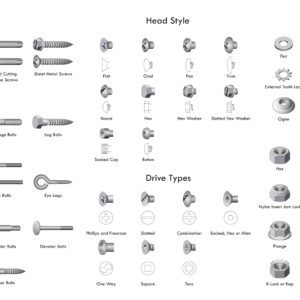

There are many features to consider when buying tek screws. You must determine: the Head Style, Length, Material, Point Type, Plating, and Shank Size.

Most of the features are self-explanatory, however, there are many things that you must be aware of:

- Length

On certain tek screws (hex head, pan head and pancake heads screws) the screw length measures from right below the head to the tip screw, whereas, on countersunk screws, you would measure the entire screw since the full length of the screw would be embedded into the material. - Point Type

When going through a thicker volume of material, the drill point type should be carefully considered. The two common types are for Light Section (#3) and Heavy Section (#5), but point styles start from #2 up to #5. When the number is higher, the volume they can go through increases - Material

The most common tek screw is manufactured in Carbon Steel. However, you also have available stainless-steel and Bi-Metal. Bi-Metal is where the tip is carbon steel, but the body is a non-magnetic stainless.

They are designed for multiple functions and applications and are similar to a drywall screw. The most common uses for tek screws are securing metal to wood and also to fix metal onto metal.

Advantages of using self-drilling screws is that you can save money. As they do not need a pilot hole to cut and fasten them, you do not need to pay extra money for drill parts. Due to this, it makes them a simpler screw to use by saving you the additional work of drilling and fastening them.

Self-Tapping Screws

These are screws that can be tapped into various types of materials, which the name implies. This includes multiple materials such as brick, metal, polycarbonate and wood – also includes materials such as aluminium, brass and iron.

Self-Tapping Screws are most commonly used for securing metal brackets onto wood or inserting screws into sturdy applications. They are sometimes referred to as: sheet metal screws, tapping screws, metal screws or tapper screws for short.

There are two main tip shapes which depends on the type of thread function it has. You have a pointed tip, which is used for thread-cutting, it taps and creates threads in a pre-drilled hole. Also, a flat tip which are thread-rolling, it rolls and extrudes threads whilst creating no clearance between the material and the screw.

Unlike Self-Drilling screws, a main factor is you can not drill through metal without a pilot hole being pre-drilled before installation.

With drilling before installation, you can create a pilot hole that is slightly smaller than the screw which allows the thread to dig into the material it secures and fastens the materials together. You must consider the size of the punch hole before as this needs to be exact when using these screws. If the hole is too big, it can become loose very quickly or fail to thread against the material. If it is too small, it can split the material due to excessive pressure.

An advantage of self-tapping screws is the variety of sizes that are available as well as the types. This makes it more customisable for your specific installations. They are also more ideal for softer materials

In summary, although both are quite similar, they are better suited to different styles of installations. Self-Tapping screws can be differentiated by having a pointed, blunt or flat tip. They also need a pilot hole before installation whereas a tek-screw doesn’t.